First solar powered LVS is a success at Teranga Gold, Senegal Africa Project Details [...]

Underloading

Underloading can cost you a fortune! We help optimize loading & increase trucking factors to improve profits.

Overloading

Overloading large trucks by as little as 10% could substantially increase fuel consumption & CO2 emissions.

Carryback

Managing carryback to improve operations. Carryback is accounted for, improving accuracy of loads shifted.

“Less carryback, more tons out of the hole, the less fuel, less CO2. It’s better for everyone,” — Graham Gibson, Senior Geologist

Installing the LVS system resulted in the trucks being loaded to capacity and has increased trucking factors by 9.7%, ultimately resulting in a lower cost per tonne hauled.

Underloading

Underloading can cost you a fortune! We help optimize loading & increase trucking factors to improve profits.

Overloading

Overloading large trucks by as little as 10% could substantially increase fuel consumption & CO2 emissions.

Carryback

Managing carryback to improve operations. Carryback is accounted for, improving accuracy of loads shifted.

Latest News

Teranga Gold Senegal Africa – Case Study

First solar powered LVS is a success at Teranga Gold, Senegal Africa Project Details CATEGORY: Mining [...]

Managing Haulback

Managing Haulback is a common problem wherever material is being shifted and can seriously impact productivity and profits.

Oversupplying

The LVS system reports the actual loose volume of the load as it sits in the truck at the time of measurement, regardless of how it was loaded or how heavy or wet the material is.

“Less carryback, more tons out of the hole, the less fuel, less CO2. It’s better for everyone,” — Senior Geologist. READ MORE…

Installing the LVS system resulted in trucks being loaded to capacity and increased trucking factors by 9.7%, lowering cost per tonne hauled. READ MORE…

Loadscan’s laser volume scanner system is helping Fulton Hogan keep track of more than a million cubic metres of material across three different sites. READ MORE…

Our trucks have shorter stops as you can lose time during conventional measurement. There is also little effort in checking the delivered quantities at our disposal site. READ MORE…

The Loadscan technology has helped us improve our daily efficiency on larger mass hauling jobs by allowing us to increase our daily production by 5-8%. READ MORE…

The team at Makies were looking for a reliable and accurate alternative measurement system to traditional weighing systems for a new quarry operation. READ MORE…

Shipping more than a few hundred thousand cubic yards of material each year from seven different production facilities, we wanted to make sure of accuracy of information on outbound loads. READ MORE…

It removes all doubt for both the seller and purchaser and reduces workload related to queries about load size, and it will pay for itself in half the time you expect. READ MORE…

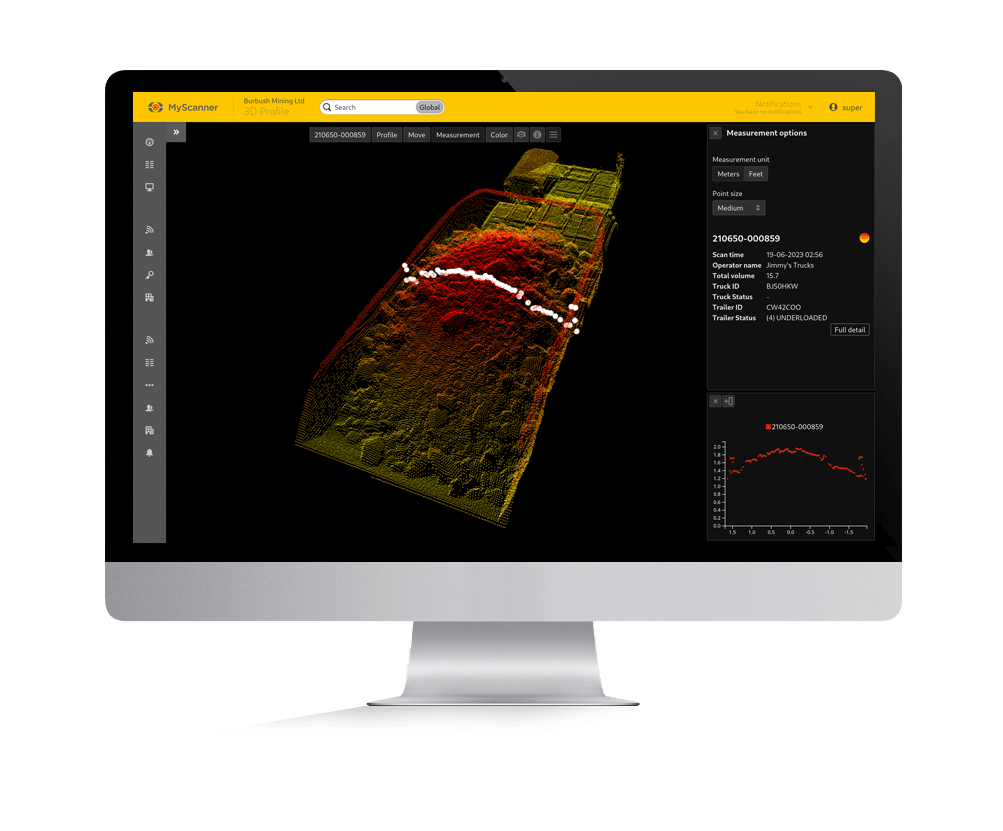

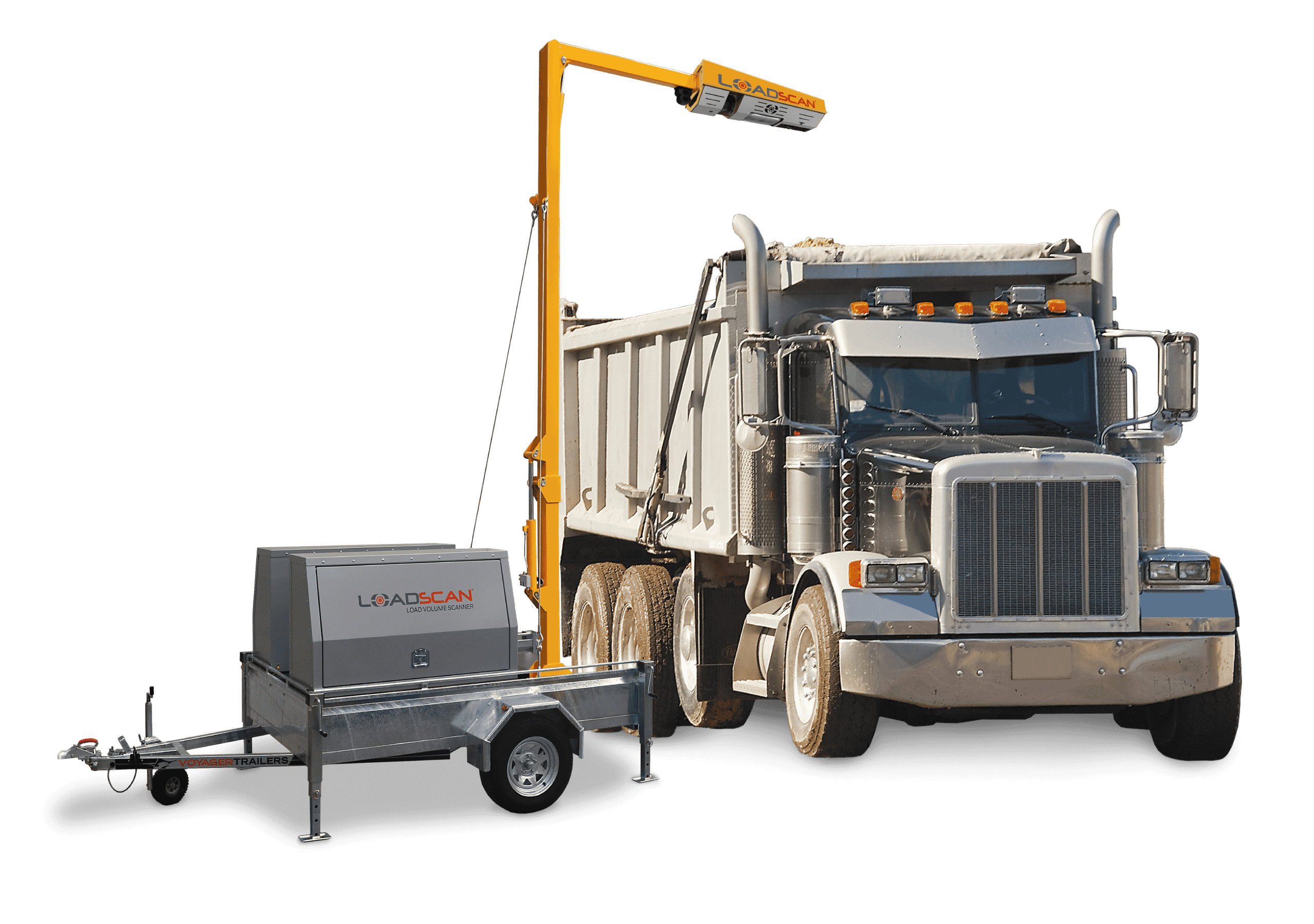

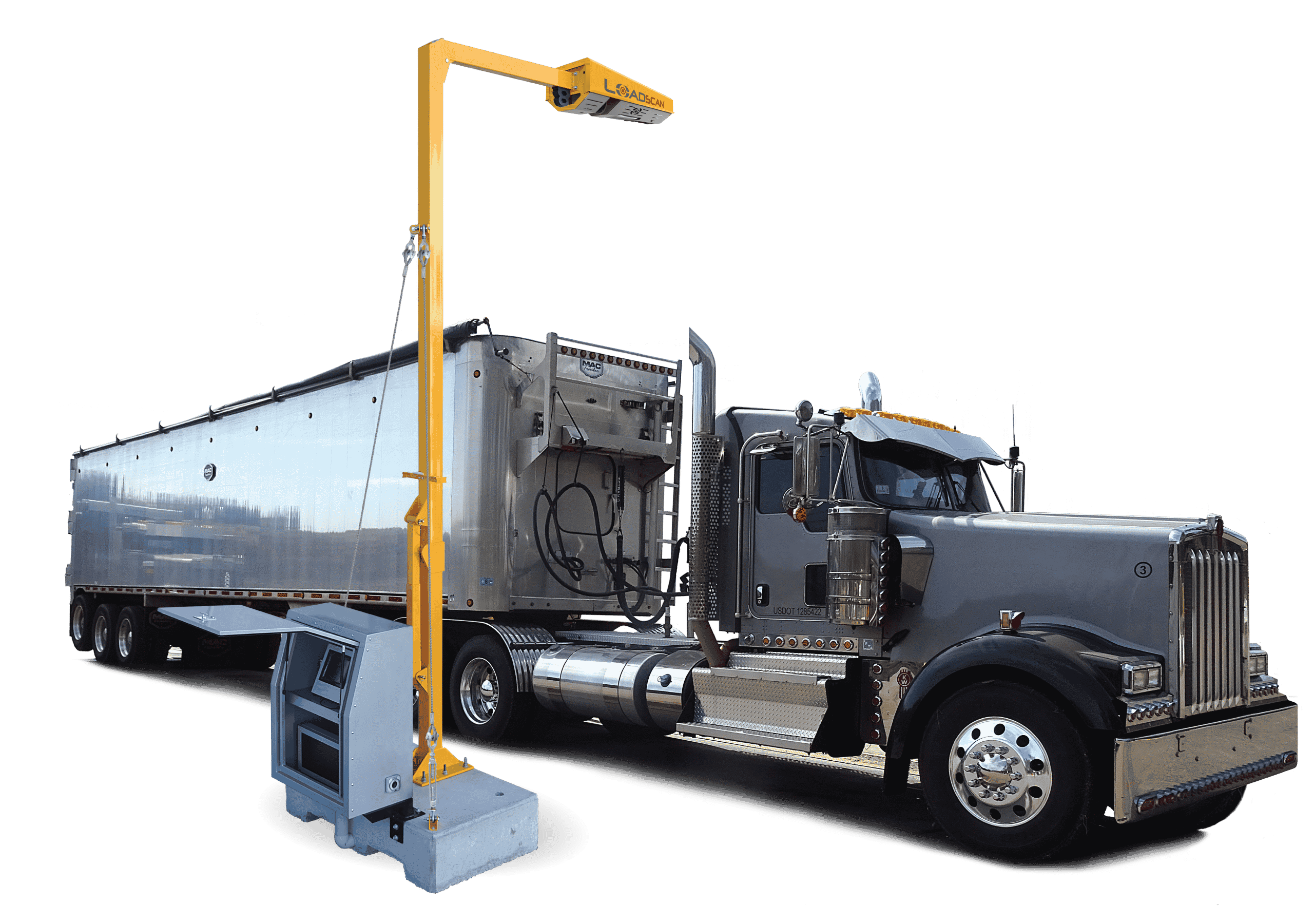

Load Volume Scanner

The Loadscan Load Volume Scanner (LVS) system utilizes laser scanning technology, combined with proprietary Loadscan software, to measure the exact volume of the material loaded in a truck or trailer bin. With this system, you’ll measure actual volume, not a converted weight estimate, whilst also recording a 3D color profile of every load.

RELATED PRODUCTS

Conveyor Volume Scanner

Manage and optimize material flow with the mine-specific Conveyor Volume Scanner (CVS). It’s a viable measurement alternative to traditional weight-based systems and, with a measurement accuracy better than 98.5%, the CVS enables accurate real-time inventory tracking and reporting.

If you want to more effectively understand your production flow rate, the CVS is the perfect solution.

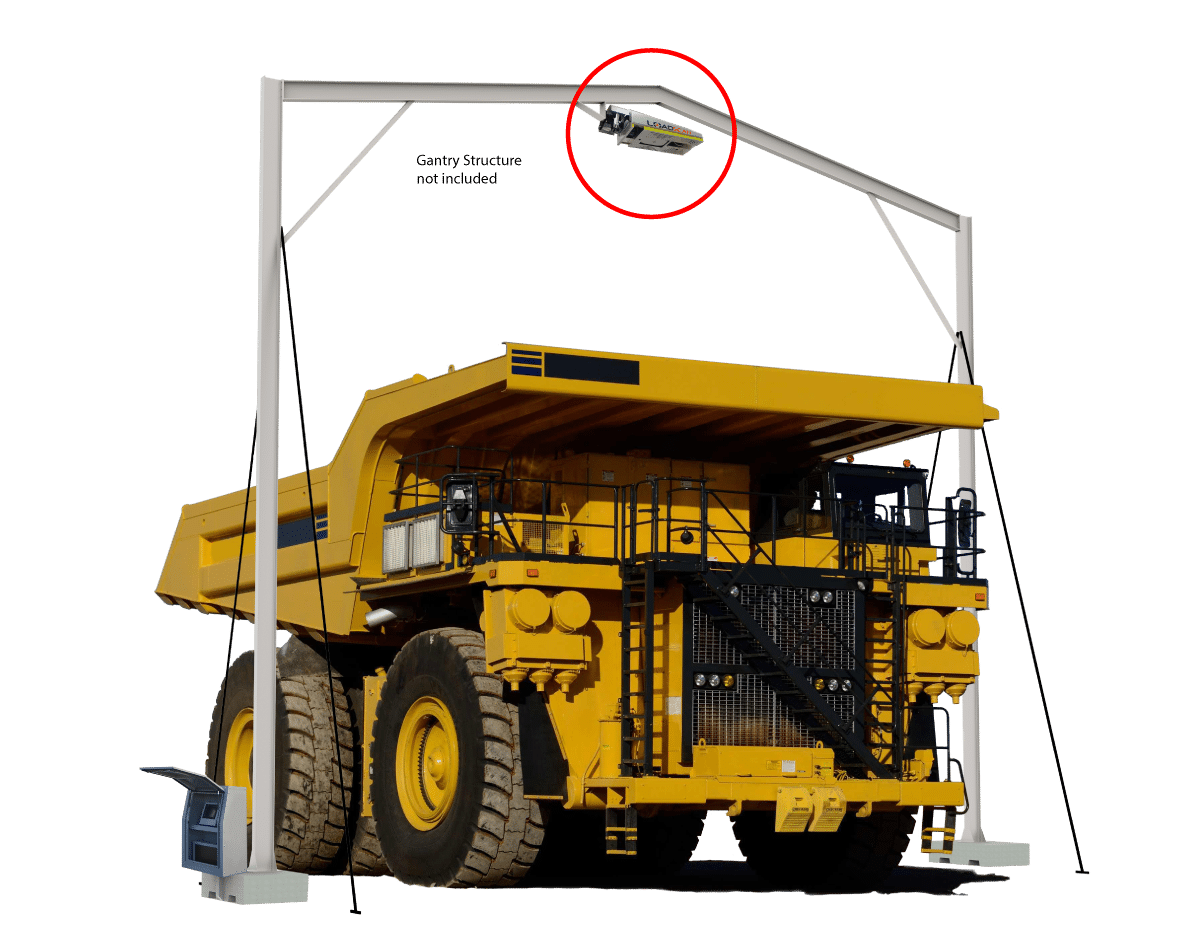

Mine Payload Scanner

Loadscan’s innovations in mining are satisfying growing global demand for reliable and accurate load measurement across a range of increasingly challenging surface and underground mining operations.

The new Mine Payload Scanner (MPS) sets a new standard for volume measurement in the industry.

RELATED PRODUCTS

Conveyor Volume Scanner

Loadscan’s Conveyor Volume Scanner (CVS) measures and reports on bulk flow to give you enhanced production control and effective stockpile management. It’s a viable measurement alternative to traditional weight-based systems and, with a measurement accuracy better than 98.5%, the CVS enables accurate, real-time inventory tracking and reporting.

Conveyor Volume Scanner

Loadscan’s Conveyor Volume Scanner (CVS) measures and reports on bulk flow to give you enhanced production control and effective stockpile management. It’s a viable measurement alternative to traditional weight-based systems and, with a measurement accuracy better than 98.5%, the CVS enables accurate, real-time inventory tracking and reporting.

Load Volume Scanner

The Loadscan Load Volume Scanner (LVS) system utilizes laser scanning technology, combined with proprietary Loadscan software, to measure the exact volume of the material loaded in a truck or trailer bin. With this system, you’ll measure actual volume, not a converted weight estimate, whilst also recording a 3D color profile of every load.