Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Loadscan reveals that quantities received and delivered are way off

Project Details

| CATEGORY: | Civil Construction |

| LOCATION: | Brisbane, Australia |

| PRODUCT: | LVS-3BMP Portable |

Think you know the amount of material you’re supplying or receiving? A Brisbane based civil construction company thought they did until they installed a Loadscan load volume scanner. The results were way off…

Background

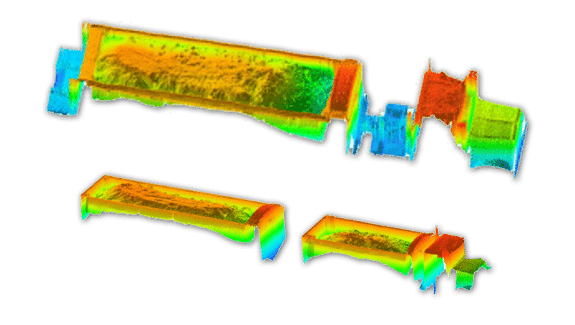

Each truck was fitted with a RFID tag for automatic identification and was scanned empty for a database reference to calculate payload in m³.

Each load was scanned on exit and the total export material measured was 1667 loads at 34,559 m³.

This report illustrates by utilising the Loadscan system what commercial benefits exist and how the system can be used to monitor improvements in loading consistency and productivity.

Truck types and details

Carting company billing rate per m³ exported: $6.50 per m³

Agreed truck rates:

- Truck and quad trailers: 22 m³ per load @ $6.50 per m³ = $143 per load

- Truck and tri trailers: 22 m³ per load @ $6.50 per m³ = $143 per load

- Truck and semi-trailers: 20 m³per load @ 6.50 per m³ = $130 per load

Initial results

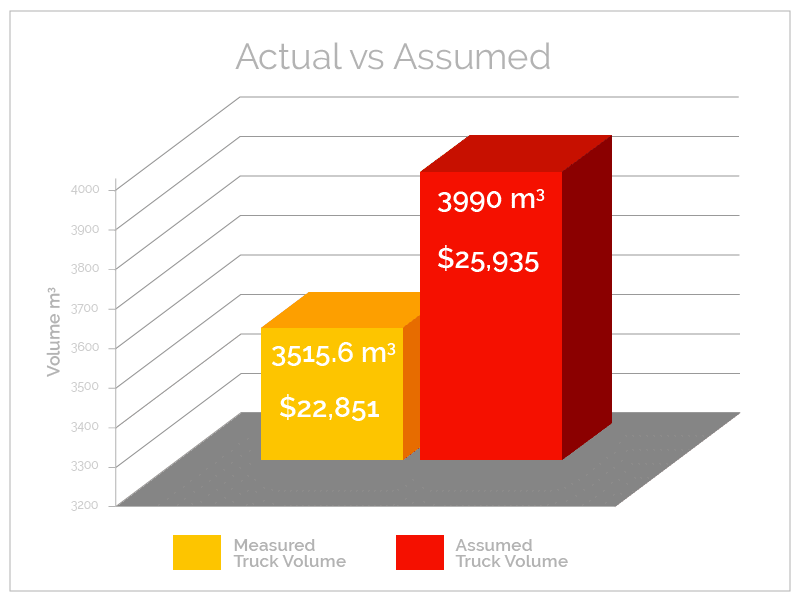

Results below show the difference between what was measured to what was being paid for on the agreed per m³ truck rate.

The calculations below are based on one shift with 187 loads

- Total of 3515.6 m³ was measured in one shift @ $6.50 per m³ = $22,851.40 per day

- Total of 3990.0 m³ agreed truck rate of @ $6.50 per m³ = $25,935.00 per day

Difference of 474.4 m³ = $3,084.00 per day

Assuming the same loading practice and truck loads per day,

- $3084.00 x 6 days week = $18,504.00 loss per week

- 474.4 m³ x 6 day week = 2846.4 m³ of export equates to approx. 130 truckloads at a 22m³ per load factor not being carted.

- 8 weeks would equate to $148,032.00 (22,771.2 m³)

Productivity

Results from the following week below show the increase in productivity and difference between what was measured to what was being paid for on the agreed per m³ truck rate.

The calculations below are based on one shift with 114 loads:

- Total of 2360.1 m³ was measured in one shift @ $6.50 per m³ = $15,340.65 per day

- Total of 2420 m³ agreed truck rate of @ $6.50 per m³ = $15,730.00 per day

- Difference of 60 m³ = $389.35 per day

- $389.35 x 6 days week = $2,336.10 loss per week

60 m³ x 6 day week = 360 m³ of export equates to approx. 16 truckloads at a 22m³ per load factor not being carted resulting in a big reduction in ‘lost cubic meters’.

Summary

Loadscan provides more accurate measurements of material movements when compared to traditional methods.

- Big opportunities to reduce export carting costs and increase your profit.

- Billing carting company for m³ measured not assumed.

- Big improvements in loading consistency and productivity.

- Load to target volume to manage truck specific mass load limits.

- Compliance with mass load limits will reduce the risk of fines for overloading.

- Chain of responsibility.