Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

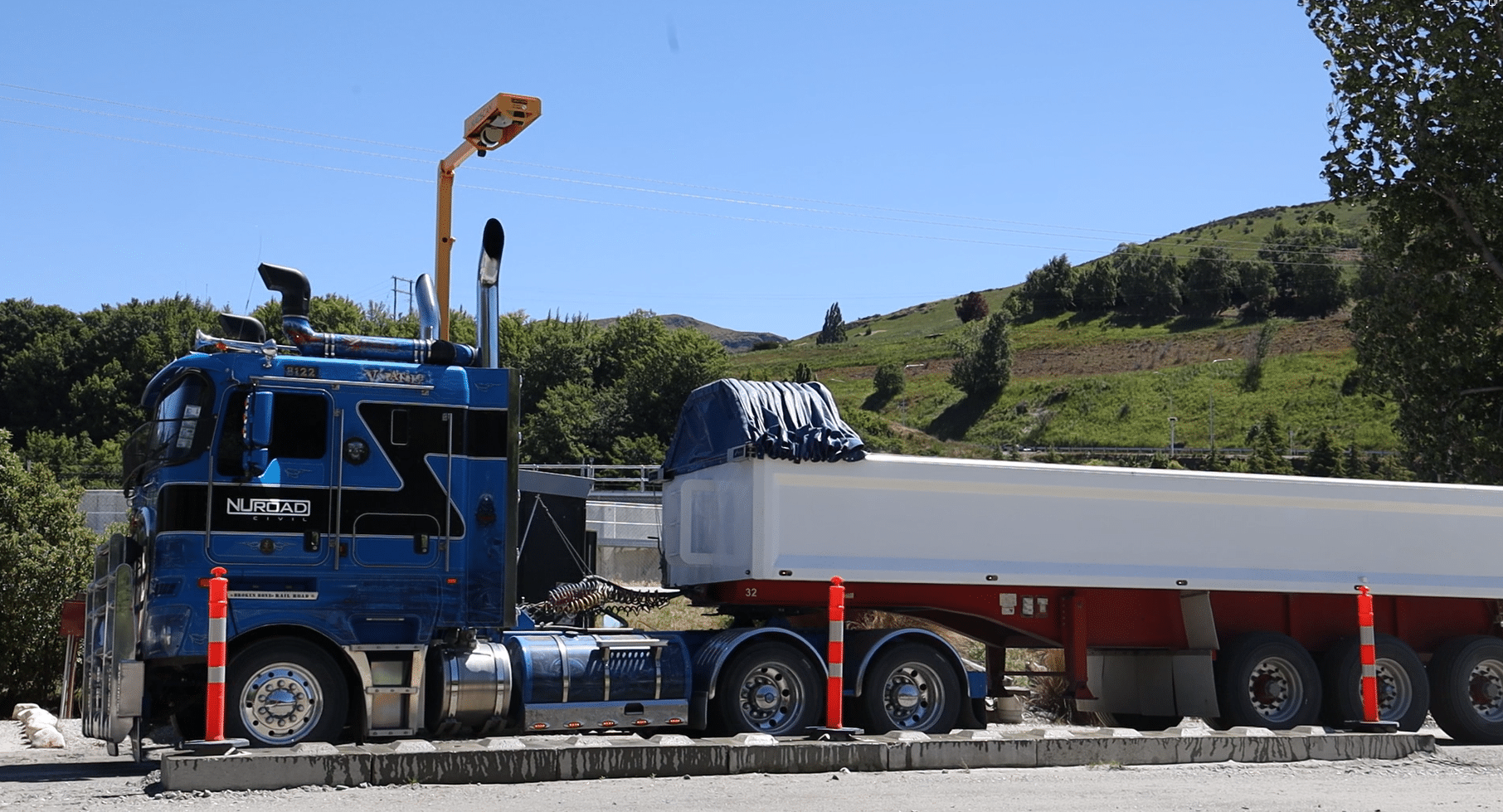

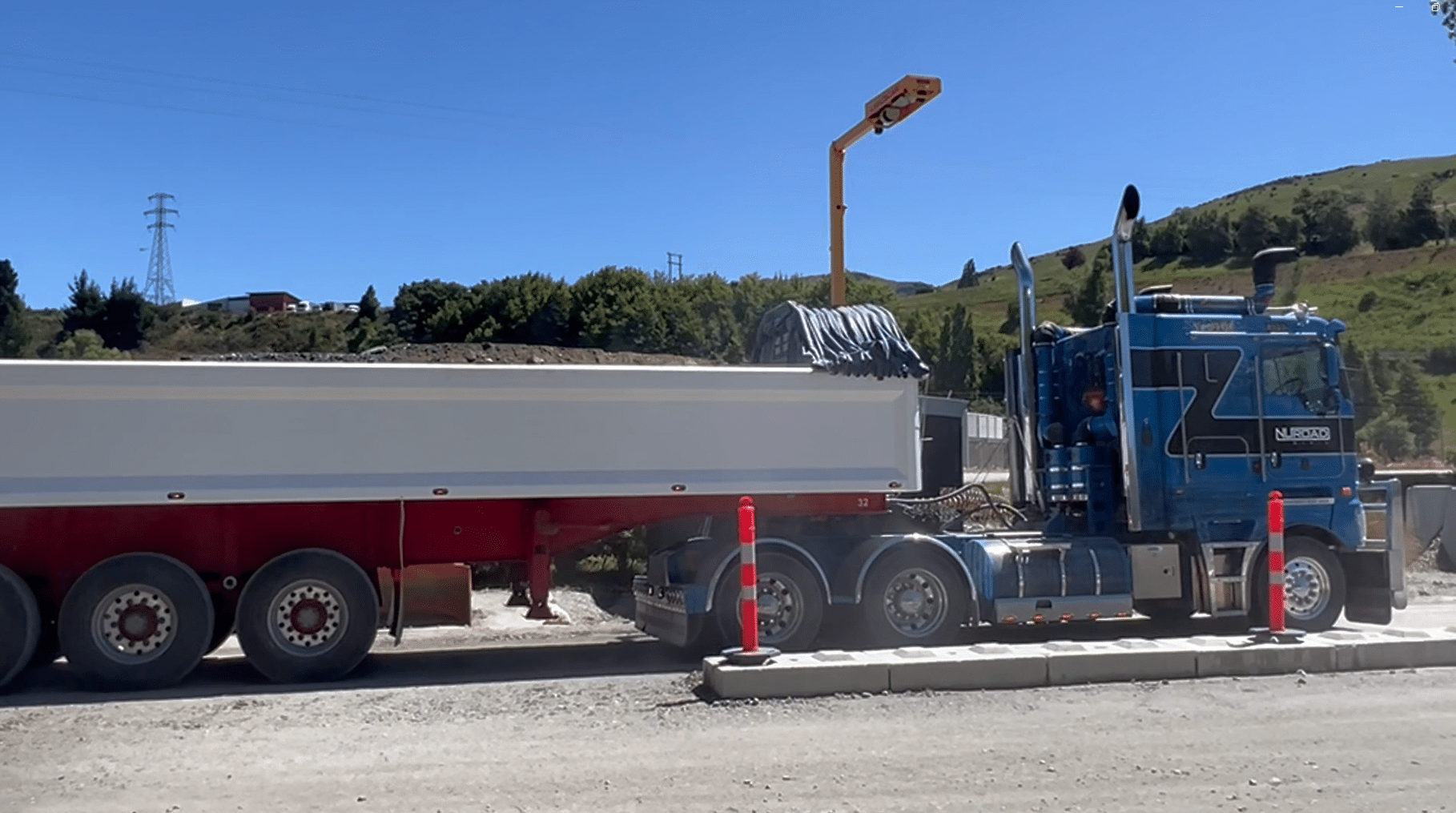

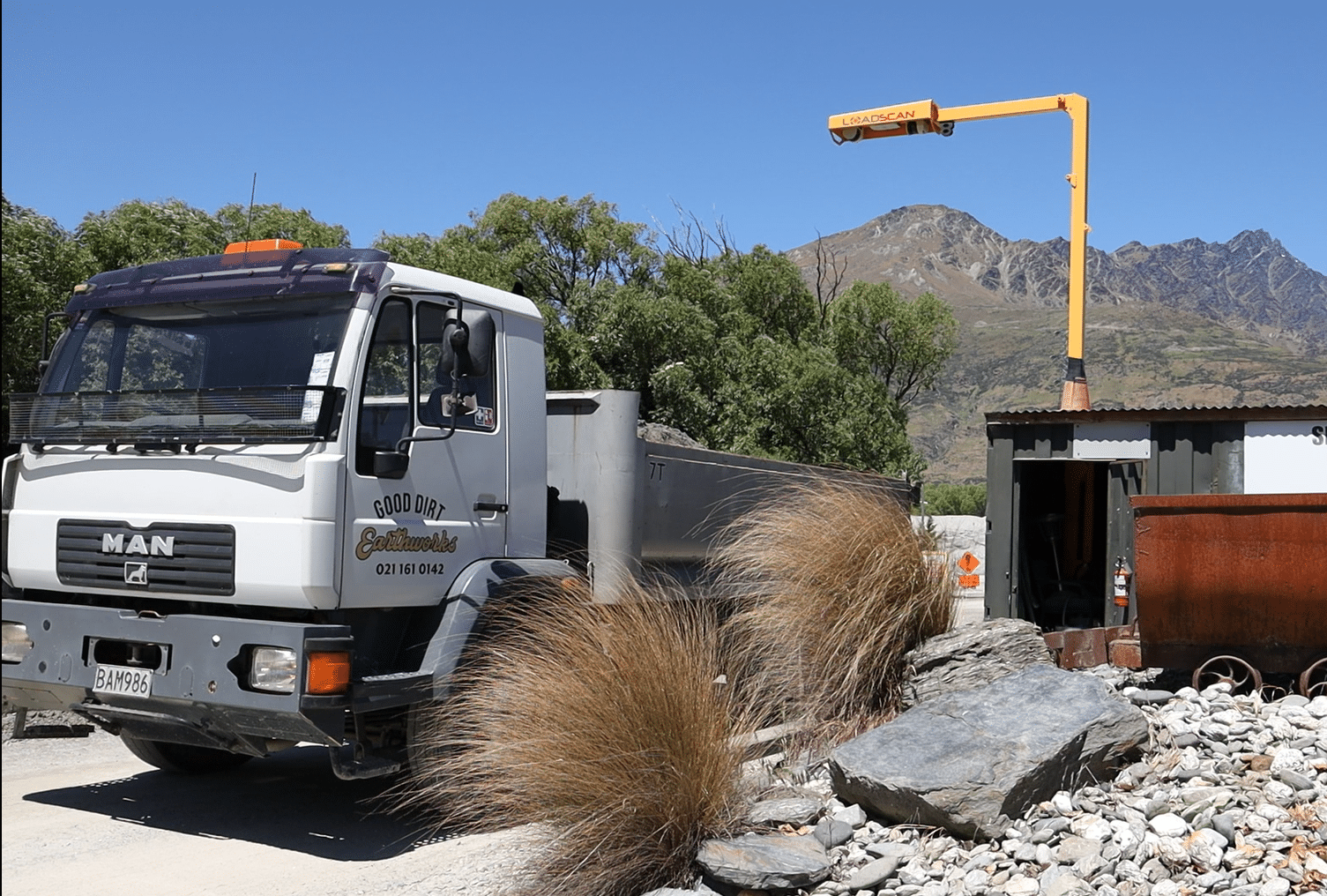

Loadscan transforming operations at Queenstown Hardfill

Project Details

| CATEGORY: | Quarries |

| PRODUCT: | LVS 3BMF |

| LOCATION: | Queenstown, New Zealand |

At Queenstown Hardfill, the business revolves around efficiently managing materials for a range of projects in the challenging terrains of Queenstown and Southern Lakes.

Company owner Steve Rout explains that the company faced significant challenges with accurate volume measurements before incorporating a Loadscan load volume scanner into their operations.

Before the addition of the Loadscan scanner, disagreements led to disputes with engineers and surveyors, and often delayed payments and strained business relationships. The tipping point came following a completed project where they had to spend a year proving their work to receive rightful payment.

“We used to keep quite a good paper record of everything, so eventually, after 12 months, we were able to prove we’d done it, and we got fully paid,” Steve says. “But by then, we were bloody sick of having these arguments and discussions and negotiations that go backwards and forwards while your cash flow is tied up….and it becomes quite adversarial, when you’re dealing with a big chunk of dough.

“After that, we got the first trailer-mounted [Loadscan] unit, and it just ceased the problems.”

As an early adopter of the load volume scanner, Steve put the machine to work and it quickly became an invaluable asset to their operations. The unit’s mobility and efficiency addressed the absence of weighbridges in remote sites, allowing them to accurately measure and record materials without relying on subjective weight estimates.

“When you’re out on sites, you don’t have weighbridges, and we were a long way from the nearest town – 50km at least – so you just don’t have that availability,” he says.

“We operate off a lot of remote sites and we can measure accurately what we’re doing, because our projects are always priced by volume.”

While the company’s original scanner is still in operation at Queenstown Hardfill’s Glenorchy gravel pit, a second, newer Loadscan LVS-3BMF model is employed at the company’s Queenstown headquarters where it continues to deliver accuracy and reliability of volume measurements into and out of the site.

“On this site, we use it for material out; we put out quite a significant volume each year, and we also run a transfer area here where small trucks and trailers and smaller contractors bring material and we take it by truck and trailer to larger sites, which we manage as part of our operation.

“So, once again, it’s time and accuracy. There’s no doubt of what came in or what went out…and there’s no argument with it.”

The key advantage of the Loadscan LVS is its ability to measure volume directly, eliminating the need for conversion to weight. Steve says they’ve resisted the industry trend of converting everything to tonnage because it introduces uncertainties and risks.

“We’ve got materials in this district that run from about 1.2 tonne a cube up to about 2.3 tonne a cube. So, your guys are always trying to estimate, is this hard, is it loose, is it soft, is it really heavy and dense, how much airspace is in the load?

“So these are all the things that drove us to thinking we have to find a better way that can be scanned quickly, and then there’s no argument; no argument about what we deliver to our client, no argument about what we take out of a site.”

Initially implementing Loadscan’s volume scanner took some time for widespread acceptance, as sceptics questioned its accuracy. However, they swiftly validated its precision by cross-referencing scans with on-ground measurements, earning the trust of engineers and contractors alike.

“Once we bought the first scanner, it took about six months to get acceptance.

“A lot of people didn’t think it was accurate, but we were able to prove very quickly it was. We surveyed truck loads — we’d tip it out on the ground and survey it and verify it.

“After that, most of the engineers accepted it.”

Contract clarity

Loadscan has also become integral to Queenstown Hardfill’s pricing system, serving as the basis for volume measurements in their contracts.

“We changed our quoting system to be based by volume measure through the scanner, and we basically had that in the contract as if that’s the volume it had, that’s what we got paid for. It was part of the contract documentation and it just stopped all our arguments.

“End of story.”

This shift has brought clarity, putting an end to disputes and streamlining operations. It has proven particularly beneficial for remote sites lacking weighbridge infrastructure, where traditional measurement methods would be impractical.

The system guarantees accuracy and ensures dealings with clients have become smoother, as they appreciate the transparency and reliability Loadscan brings to their operations.

“It guarantees our QA, and we can back it up with facts,” Steve says. “So once again, it helps with your dealings with clients because they know there’s not going to be any hassle.

“If we tell them we’re bringing them 500 cubes, they get 500 cubes or, vice versa, if we’re carting 500 cubes out of their site, they know that’s what’s happening.

“It allows you to work remotely without having any issue about trust or misunderstandings.”

That trust has translated into improved cash flow, a critical aspect of their business.

“As we all know, cash flow is king now. If you haven’t got your cash flow because you’re having an argument, it affects your business.”

Beyond the financial benefits, Loadscan has helped them maintain their commitment to delivering what they promise. It has prevented potential discrepancies caused by human error or subjective judgments, creating a more efficient and trustworthy operation.

“We love the thing. We just love it. We don’t have arguments with clients anymore.”