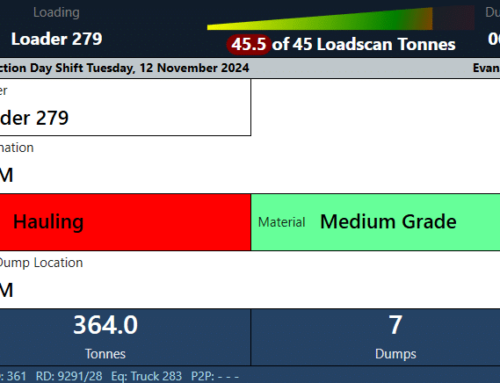

Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

New law puts safe loading in the spotlight

Australia’s Heavy Vehicle National Law (HVNL) is changing in mid-2018. The changes are not only relevant to businesses that drive or operate heavy vehicles, they will also apply to any businesses that consign, pack, load or receive goods by heavy vehicles.

This means you could be held legally liable for breaches of the Heavy Vehicle National Law (HVNL) even though you have no direct role in driving or operating a heavy vehicle. In addition, corporate entities, directors, partners and managers are accountable for the actions of people under their control.

It is now more important than ever to understand your payload weight, especially in remote quarries or sand mining locations where a full truck scale is not available.

With Loadscan’s load volume scanner you can sleep at night and take the pressure off your workers knowing that any heavy vehicle leaving your site hasn’t been over loaded.

Through the use of laser scanning technology the Loadscan system features a non-contact drive-through measurement instrument where accuracy is not affected by wear and tear on sensors like traditional weight based measurement systems. Loadscan will produce accurate results every time and is quick and easy to set up so trucks can be scanned without delay. The accuracy of the Loadscan system has been proven and validated by a process of measuring solid artefacts of known volume. Through this test method the Loadscan systems have a proven accuracy of +/- 1% or to the point of resolution which is 0.1m3

Loadscan is the only truck volume measurement system that can boast trade certification, allowing operators total confidence in the truckload measurement data.

This method of payload monitoring provides a more detailed picture of how much material is being shifted. Loadscan’s software interfaces with more office management systems than any other LVS system, accounts for haul back and supplies 3D profiles of every load to ensure you’re hauling optimum volumes. All from a single in-motion scan.

Unlike on-board weighing systems, which require ongoing servicing and calibration, Loadscan only requires a single installation with no major earthworks or fiddly calibration. There’s no need to fit out an entire fleet (or install an expensive fixed truck scale) as a single Loadscan unit provides traceable drive-through payload measurement for all trucks that pass beneath it.

For more information on Loadscan please click here.