Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

All autonomous

Autonomous mining technologies is the hot topic in the mining industry at present with Rio Tinto’s mine in Western Australia using a full fleet of autonomous trucks to haul ore out of the pit.

At Loadscan, autonomous truck profiling is not a new concept, our laser-based truck profiling systems was developed back in 1998 – it’s now time to merge the technologies to fully understand the haulage efficiency of autonomous mine trucks by scanning to reveal true load quantity upon entry and exit of the mine site.

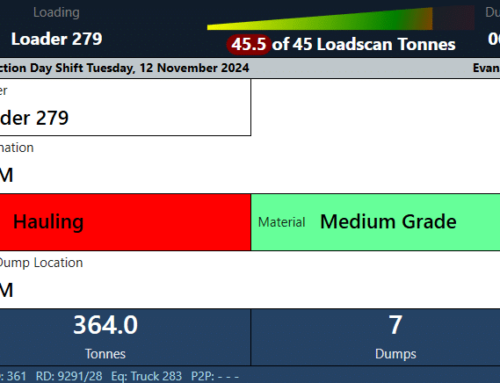

The Loadscan load profiling system gives real-time data, including live 3D imaging, of every load so fill factors and correct loading can be monitored. It provides an exact picture (with +/- 1% accuracy) of the quantity of material being extracted/hauled and scanning trucks on their return route will allow mines to monitor (and manage) wasteful haul-back.

With the Loadscan technology mines are able to keep everything in-motion round the clock. The Loadscan system records and reports on every load and the scanners will continue to measure load after load at 8kmp/h in the toughest environments. Unlike weigh bridges and scales, load volume scanners are relatively easy install and, with no wear parts, don’t require ongoing calibration or routine maintenance.

When your mine’s productivity hinges on your ability to move the maximum amount of material, as efficiently as possible, shift after shift, it makes sense to have stringent measurement and management of your trucking factors. Loadscan’s customers have reported 15% increase in trucking factors as a direct result of installing load volume scanning system.

Click here for more information about how load scanning works

Click here to go to Loadscan’s mining industry page