Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Learn how to maximise your payload with autonomous load volume scanning at EXPOMIN

Mining is the economic engine of Chile. Its successive exploitation of coal in the South, silver in Chañarcillo and nitrate in the North means mining plays a pivotal role in the country’s economy.

Loadscan will be exhibiting at this years’ EXPOMIN in Chile (find us at Hall 2, stand L-78). Alongside representatives from New Zealand Trade and Enterprise (NZTE), we will be sharing with this vital industry, how you can increase mining productivity by way of obtaining accurate load measurement data with a single drive through scan.

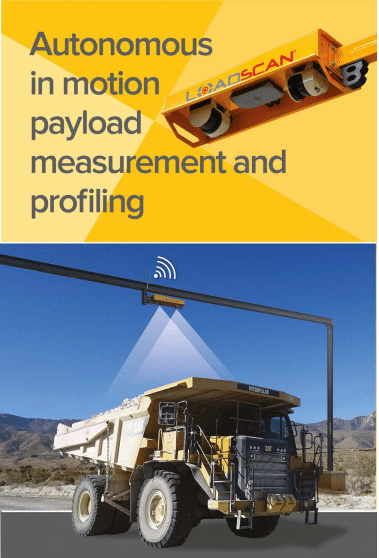

Our autonomous payload scanning solution works across all mining truck variants – including large rigid dumpers. While autonomous mining technology is surfacing around the world – it’s not a new concept for Loadscan. We pioneered load volume scanning and developed the original laser-based profiling back in 1998.

Unlike on-board weighing systems, which require ongoing servicing and calibration, Loadscan only requires a single installation with no major earthworks or fiddly calibration. There’s no need to fit out an entire fleet (or install an expensive fixed truck scale) as a single Loadscan unit provides traceable in-motion payload measurement for all trucks that pass beneath it.

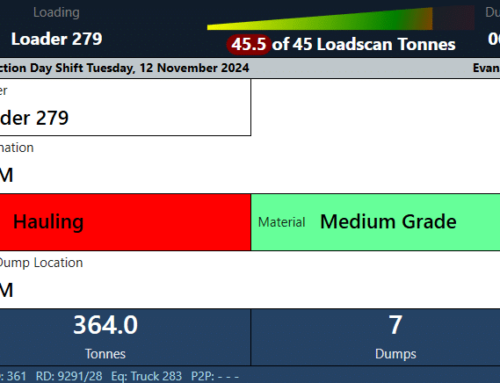

The Loadscan load profiling system gives real-time data, including live 3D imaging, of every load so fill factors and correct loading can be monitored. It provides an exact picture (with plus or minus 1% accuracy) of the quantity of material being extracted/hauled. And scanning trucks on their return route will allow mines to monitor (and minimize) wasteful haul-back.

Visit EXPOMIN for registration.

Click here for more information on Loadscan and mining.

Click here to be re-directed to our Spanish language landing page.

View our brochure here (English and Spanish translations).