How volume scanning reshapes customer relationships Tracking material volumes across multiple sites is a [...]

Inaccurate compaction and bulking factors can reduce profits

Every supplier and manufacturer has a somewhat unique situation, where material is affected to different degrees by factors such as moisture, size of the pile, how long the pile has been settled, and type of material. Using common bulking and compaction factors provide generic estimates only, and don’t necessarily reflect the actual state of your material.

Incorrectly estimated or misunderstood factors can significantly reduce profits due to material measurement inaccuracies on incoming and outgoing loads. One cubic yard in the stockpile does not translate into one cubic yard in the truck, nor one cubic yard when dumped.

Material from the stockpile tends to compact when loaded into a truck bin. When the material is unloaded at the destination it tends to bulk up, but usually not the the same volume that was extracted from the original stockpile. This makes accurate loose measurement challenging.

Without accurate factors to determine the true volume of loose material in a truck bin you could be paying for material you haven’t actually received, or you could be oversupplying your customers.

The Loadscan LVS gives you the ability to accurately determine and apply your own compaction and bulking factors of each of the materials you receive and supply, making it the only reliably accurate method of measuring volumes.

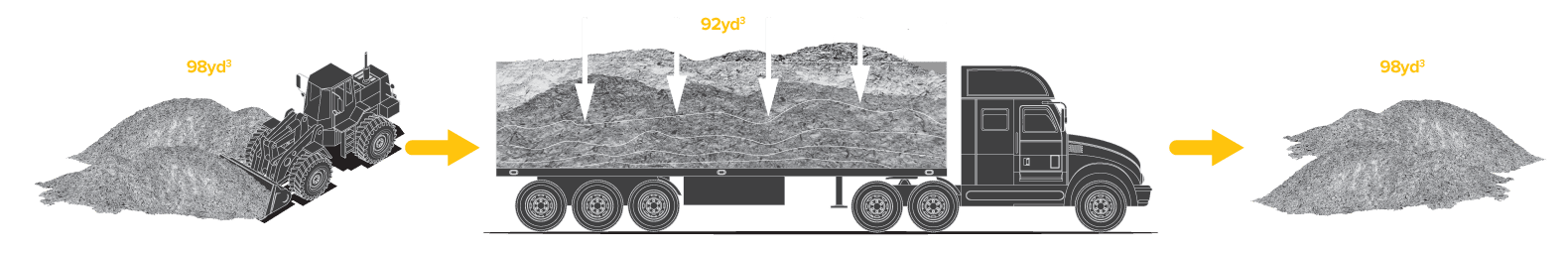

A typical example of how compaction and bulking changes the volume of material

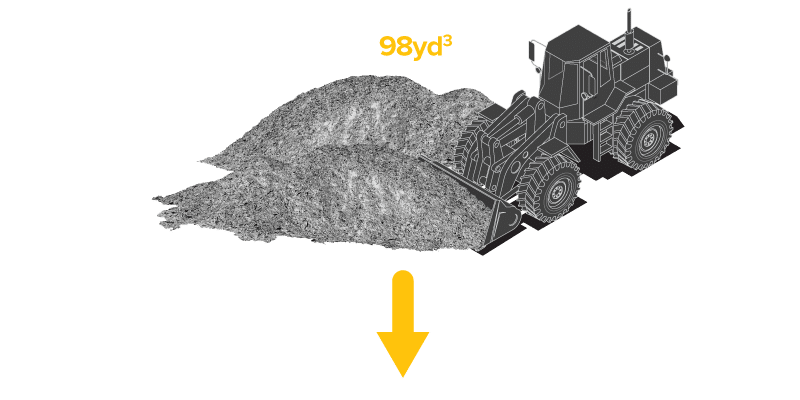

Material in stockpile

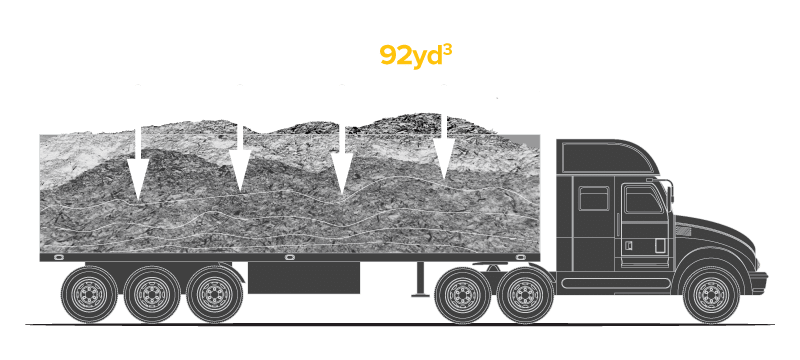

Volume reduces when loaded into truck due to compaction

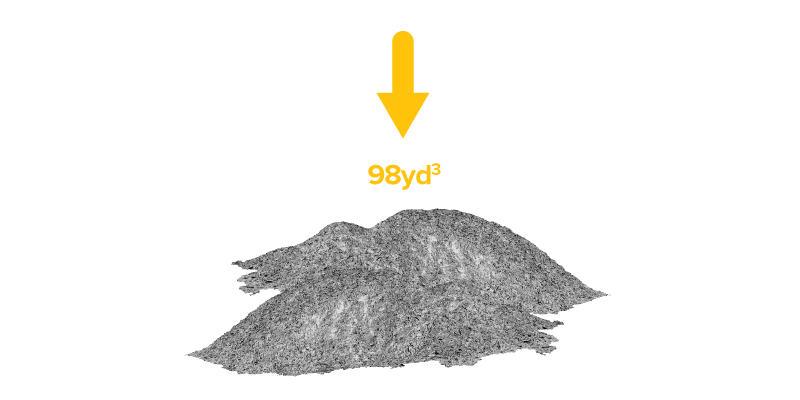

Volume increases when dumped, returning to the original stockpile volume

Inaccurate compaction and bulking factors can reduce profits

Every supplier and manufacturer has a somewhat unique situation, where material is affected to different degrees by factors such as moisture, size of the pile, how long the pile has been settled, and type of material. Using common bulking and compaction factors provide generic estimates only, and don’t necessarily reflect the actual state of your material.

Incorrectly estimated or misunderstood factors can significantly reduce profits due to material measurement inaccuracies on incoming and outgoing loads. One cubic yard in the stockpile does not translate into one cubic yard in the truck, nor one cubic yard when dumped.

Material from the stockpile tends to compact when loaded into a truck bin. When the material is unloaded at the destination it tends to bulk up, but usually not the the same volume that was extracted from the original stockpile. This makes accurate loose measurement challenging.

Without accurate factors to determine the true volume of loose material in a truck bin you could be paying for material you haven’t actually received, or you could be oversupplying your customers.

The Loadscan LVS gives you the ability to accurately determine and apply your own compaction and bulking factors of each of the materials you receive and supply, making it the only reliably accurate method of measuring volumes.

A typical example of how compaction and bulking changes the volume of material

Material in stockpile

Volume reduces when loaded into truck due to compaction

Volume increases when dumped, returning to the original stockpile volume

More solutions

More solutions

More solutions

Put an end to inefficiencies, waste, and guesswork.

Get accurate product densities

Eliminate disputes over volumes

Optimise truck loading

Proven accurate to +/- 1%

Only pay for what you receive

Don’t pay for water content

Improve customer satisfaction

Put an end to inefficiencies, waste, and guesswork.

Get accurate product densities

Optimise truck loading

Accurate volumes sold every time

Don’t pay for water content

Eliminate disputes over volumes

Proven accurate to +/- 1%

Only pay for what you receive