Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Loadscan CVS transforms operational efficiency

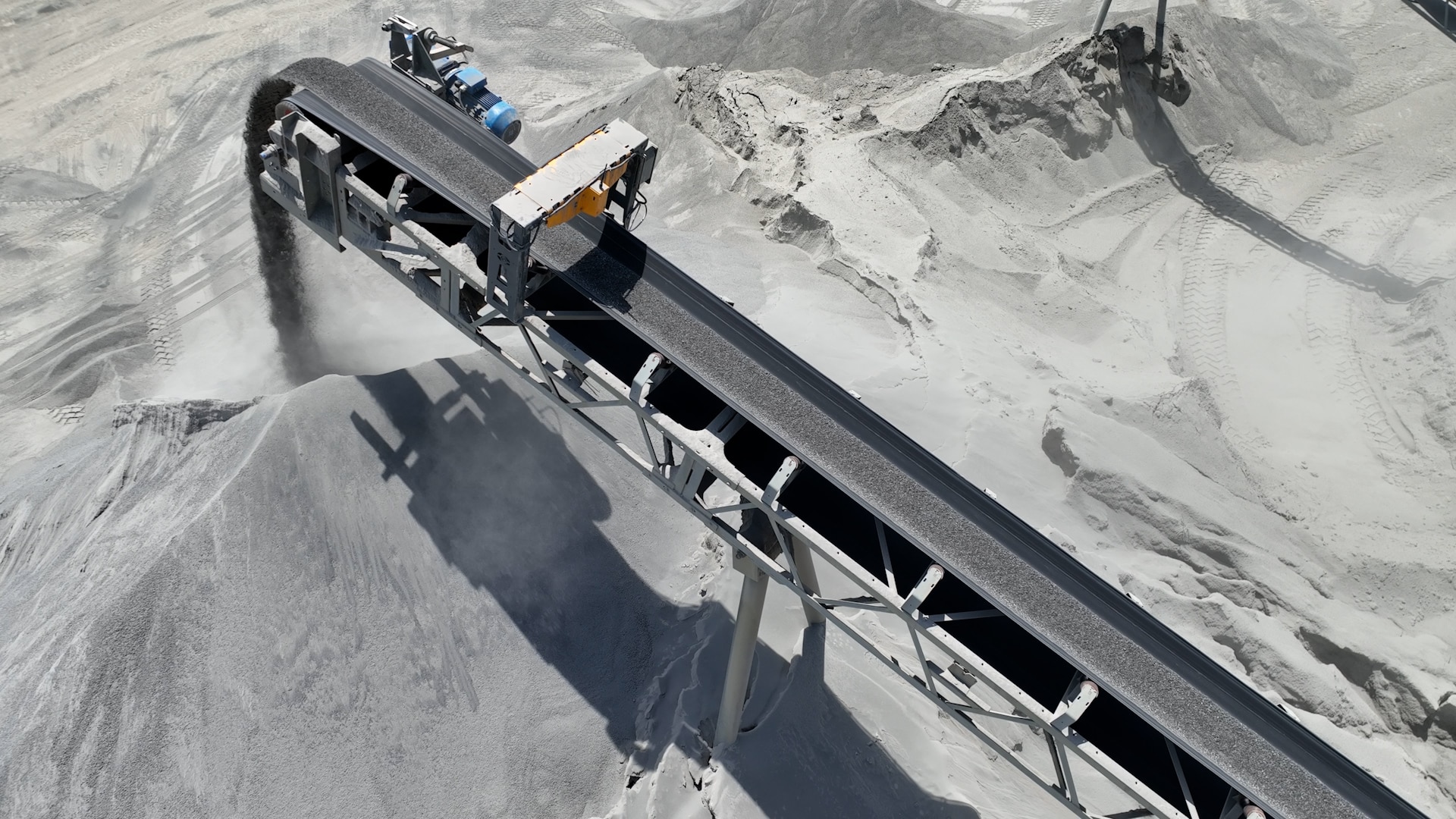

The ECON La Cantera quarry in El Salvador is one of the largest aggregate quarries in the country.

Project Details

| CATEGORY: | Quarries |

| PRODUCT: | CVS |

| LOCATION: | El Salvador |

| WEBSITE: | lacantera.com.sv |

The quarry, situated just outside the nation’s capital San Salvador, plays a crucial role in providing aggregates for infrastructure and construction projects across the region. Producing a variety of aggregates essential for development, La Cantera maintains high standards of quality and efficiency. As it has developed and grown, the quarry has continually sought ways to enhance processes and improve production efficiency, in its operations. The introduction of Loadscan’s Conveyor Volume Scanner (CVS) has significantly impacted their operations.

At the La Cantera facility, the quarry extracts approximately 3,000 cubic meters (m³) of rock daily, processing it through a range of separate crusher lines to produce various aggregate products. To manage this large-scale production, the quarry relies on several systems and technologies to maintain smooth operations. A transformative investment made recently was the installation of a number of Loadscan CVS units across all crushers, providing a number of key benefits that have revolutionized operations.

Improved accuracy in production reporting

Before the Loadscan CVS, production tracking was based on counting truck trips, which was neither precise nor efficient. The quarry estimated the production of each aggregate type by truck trips and percentages established over time. However, this method often led to inaccuracies and lacked real-time precision.

With the Loadscan CVS, production reporting has become much more accurate. The system provides precise volume measurements of extracted material, and materials throughout the day. This real-time data has simplified reporting, increased accuracy, and enabled more informed decisions regarding resource allocation.

Tracking downtime and identifying production bottlenecks

Previously, La Cantera struggled to track plant downtime accurately. Estimating idle periods was time-consuming and often imprecise. Understanding the duration of production stops is essential to optimizing efficiency.

Now, with the Loadscan CVS, the quarry can precisely track downtime, enabling investigation into the reasons for the production stops. The system logs downtime events, offering insights into bottlenecks or issues within the production process. Whether due to maintenance, truck delays, or other factors, the team can immediately identify and address inefficiencies, reducing downtime and boosting overall productivity.

Real-time monitoring of equipment efficiency

Before the Loadscan CVS, equipment efficiency assessments often occurred too late to address performance issues promptly. This delayed response contributed to unnecessary downtime and inefficient resource use.

With the Loadscan CVS, the quarry can now monitor equipment efficiency on a real-time basis. This immediate visibility allows corrective actions for underperforming equipment or deviations in the production process. For example, if a crusher operates below optimal capacity, or if a truck delays its return, the team can adjust operations right away, leading to better equipment usage and reduced downtime.

Managing stock volumes and preventing material shortages

La Cantera produces a broad range of aggregates, receiving around 200 trucks daily that are loaded with materials across 10 different product options. Accurately understanding stock volumes is vital to meeting customer demands.

Before the Loadscan CVS, stock measurements occurred infrequently, with discrepancies sometimes requiring inventory adjustments that could lead to shortages or imbalances.

With the Loadscan CVS, the quarry now monitors stock volumes in real-time. If an aggregate type is running low, the system helps quickly reassign resources—such as trucks and crushers—ensuring a consistent supply of material for each product. This proactive approach has made inventory management more responsive, reducing the risk of material shortages.

Commitment to sustainability and technology

La Cantera is committed not only to delivering high-quality aggregates but also to sustainability and innovation. The quarry operates a solar farm with more than 4,000 solar panels, generating enough energy to power the entire facility. The addition of the Loadscan CVS aligns with the quarry’s broader commitment to using advanced technology for efficiency and sustainability.

By implementing the Loadscan CVS, La Cantera has enhanced operational efficiency, reduced waste, and improved stock and resource management, reinforcing its commitment to quality, environmental responsibility, and technological advancement.

The decision to install Loadscan’s CVS across all crushers at La Cantera has proven to be one of the company’s best investments. The system’s ability to improve production reporting accuracy, track downtime and equipment efficiency, and manage inventory in real-time has transformed operations. This technology has optimized productivity, reduced inefficiencies, and ensured preparedness to meet customer demands. Furthermore, it strengthens the quarry’s commitment to sustainability and technological innovation. The integration of Loadscan has not only enhanced operational performance but also set the stage for continued improvements in the future.