Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

Overloading massively increases fuel costs and CO2 emissions

In an Australian technical paper titled, “Haul truck fuel consumption and CO2 emission under various engine load conditions”, the researchers determined that overloading a large mining truck (CAT 797B) by as little as a 10% could increase fuel consumption and costs by nearly US$367,000 per annum and add 900mt CO2 emissions per truck.

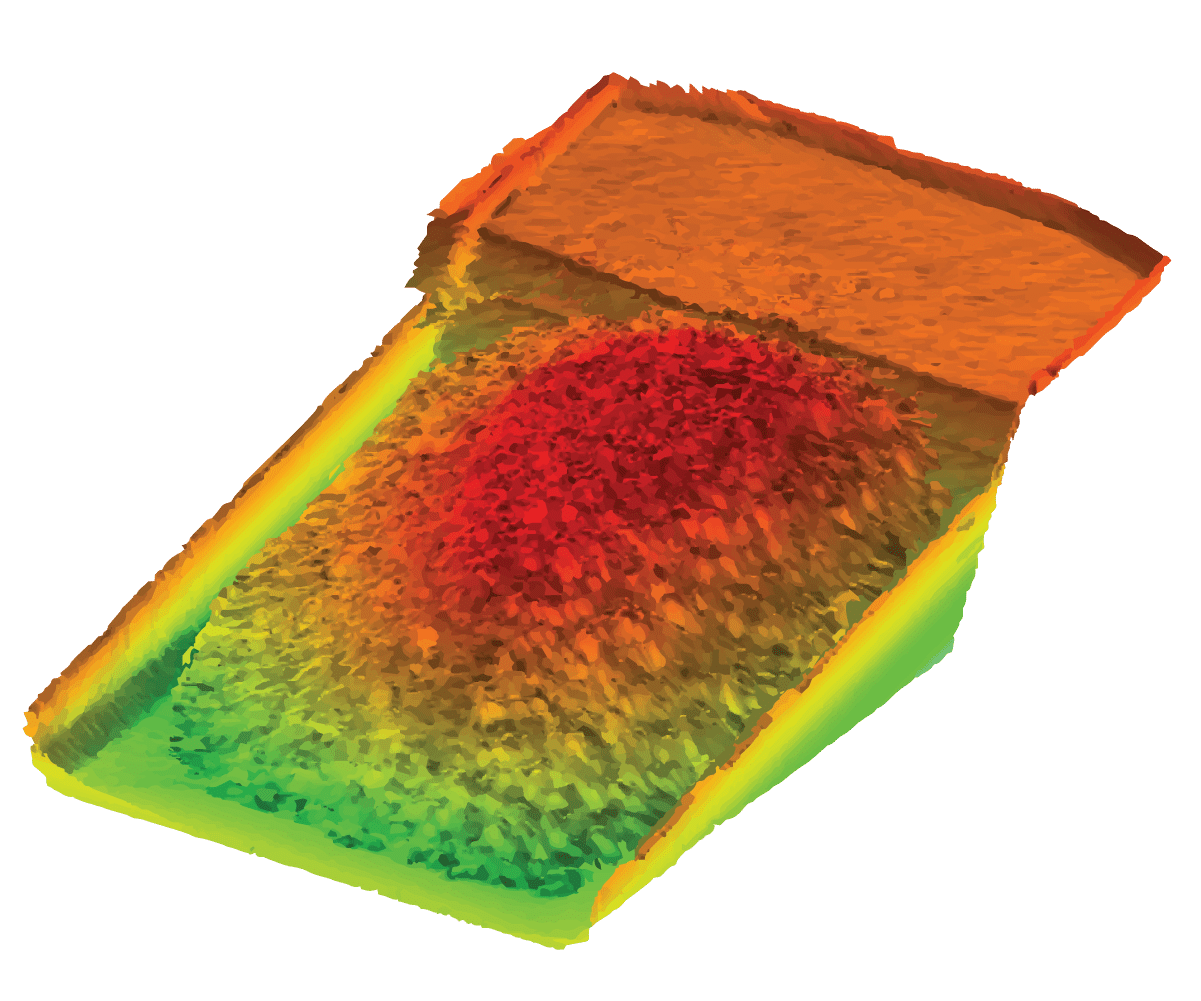

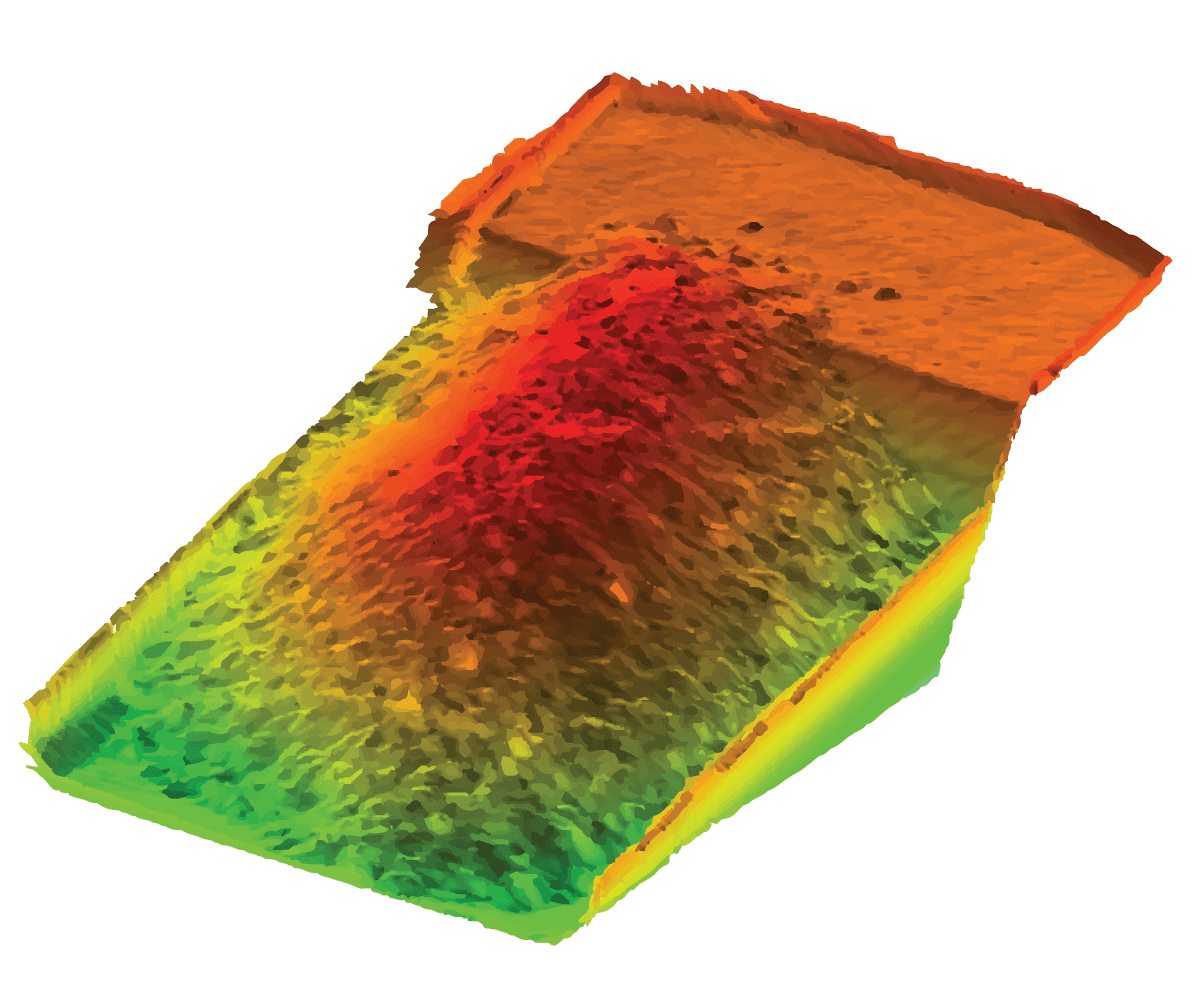

OPTIMALLY LOADED (nominal capacity)

380 tonnes = 253m³

COMMONLY OVERLOADED (10%)

418 tonnes = 278m³

(Based on bulk density factor of 1.5)

Key research findings…

Fuel Savings — CAT 797B

CO2 Savings — CAT 797B

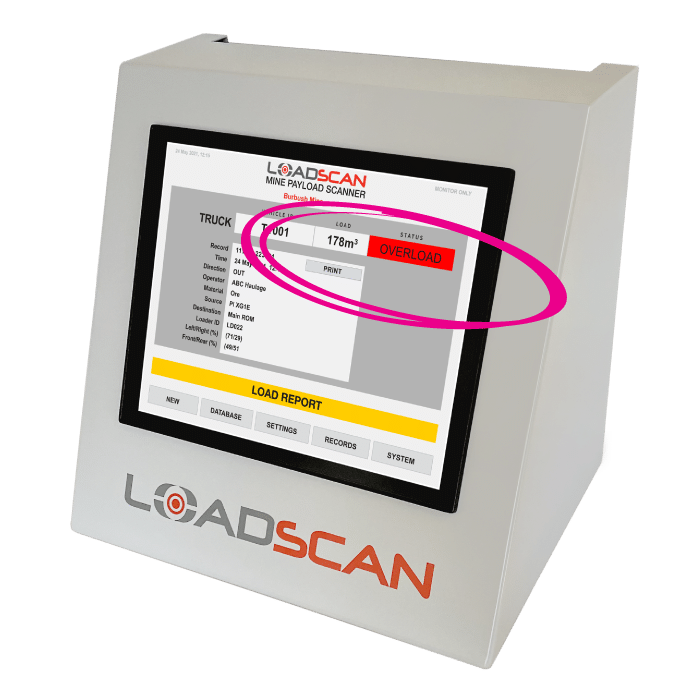

The volumetric Mine Payload Scanner (MPS) is a viable truck scale alternative. It enables mines to identify sub-optimal loading in real time and to take immediate corrective action.

DATA SOURCE: Kecojevic, Komljenovic, 2010, “Haul truck fuel consumption and CO2 emission under various engine load conditions.” All costs shown in USD.

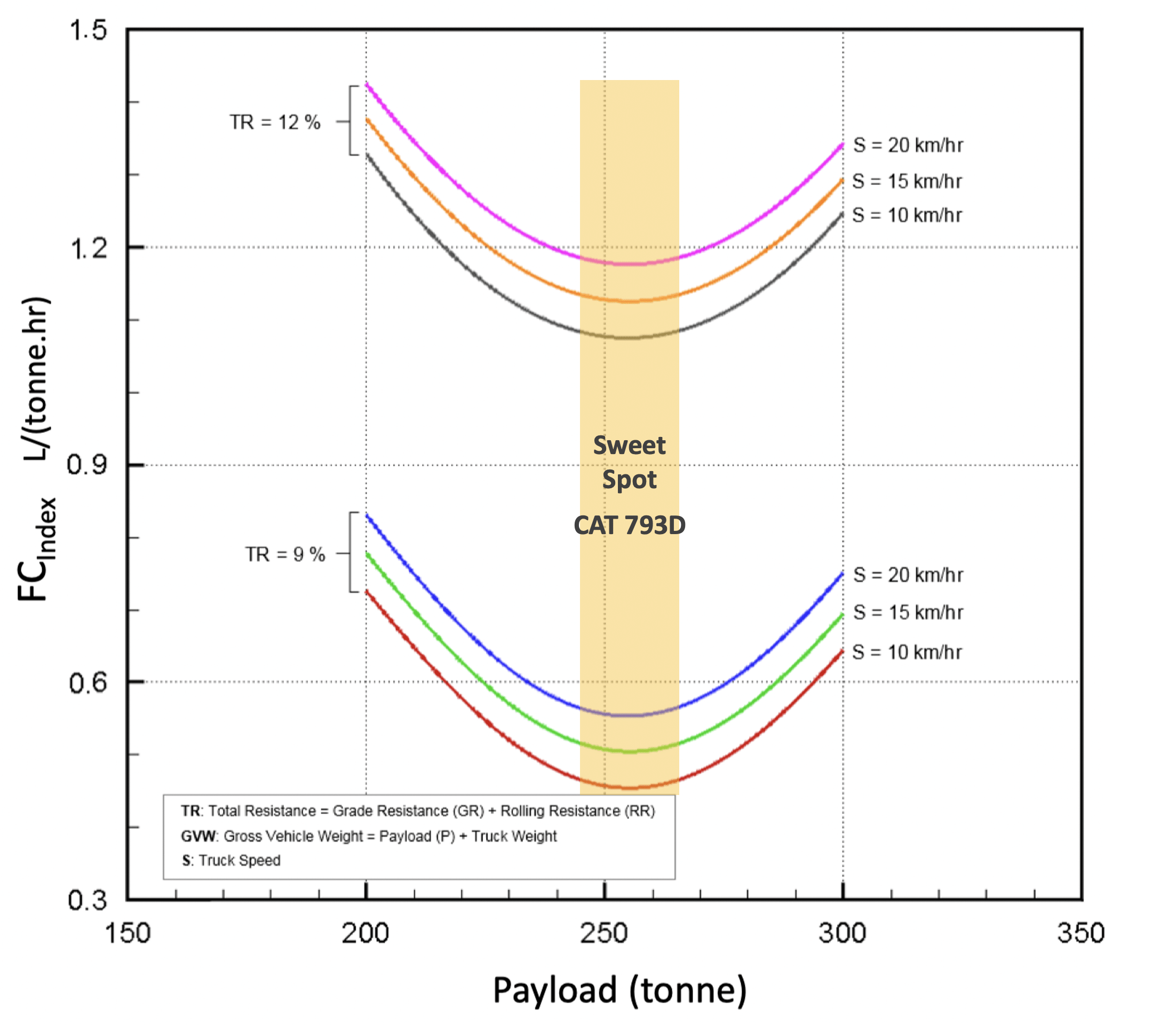

Optimum loading has a significant influence on fuel consumption

With big mining trucks, fuel is a major cost contributor. Analysis carried out by the University of Queensland into fuel consumption relative to load size shows some interesting facts.

Based on an analysis of CAT 793D trucks (250 tonne rated capacity), it was found that when underloaded, fuel consumption increased at a similar rate to when overloaded! It became evident that there is an optimal loading ‘sweet spot’ where fuel consumption (and resulting CO2 emissions) are optimized.

The Mine Payload Scanner (MPS) enables mines to identify sub-optimal loading in real time and to take immediate corrective action. The MPS is a key weapon in helping to reduce unnecessary fuel consumption and CO2 emissions.

DATA SOURCE: University of Queensland, “Reducing Fuel Consumption of Haul Trucks in Surface Mines Using Artificial Intelligence Models”