Optimizing Mining Operations with Pitram and Loadscan Integration at CSA Cobar The MAC [...]

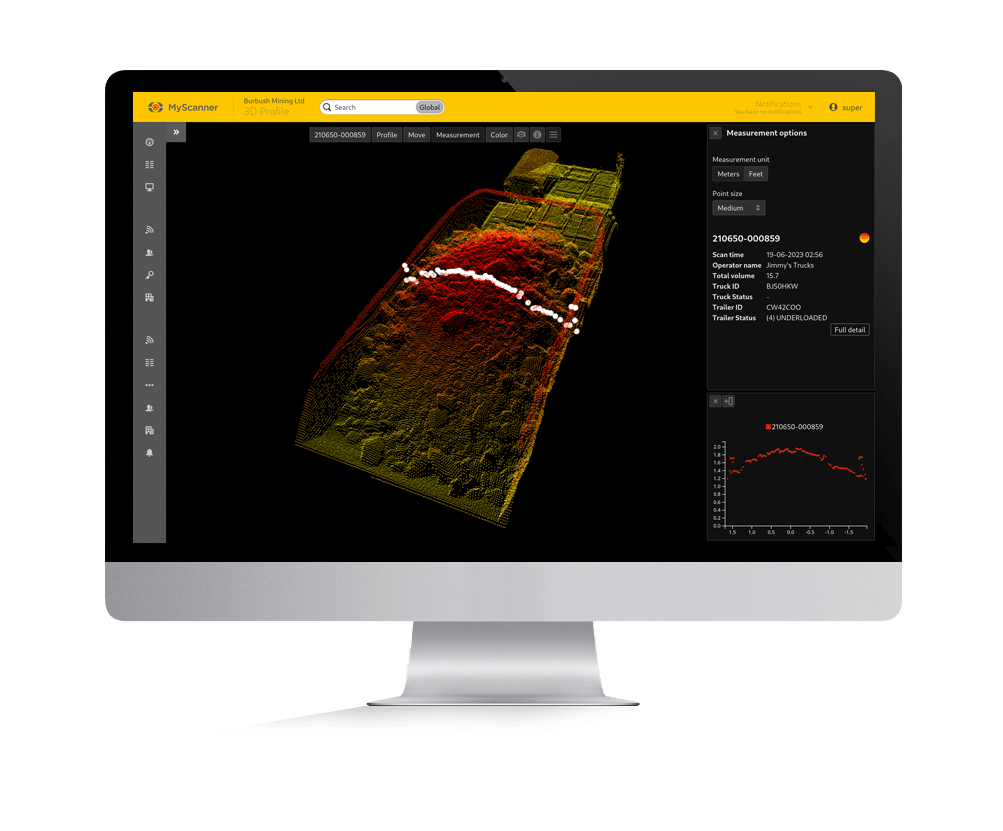

3D Payload Profiler

Reduce tyre and machinery wear, increase truck fill factors and improve payload safety with load distribution graphics and statistics for performance monitoring to visually educate and train operators in optimizing payload efficiency. LoadScan 3D Payload Profiler has been developed to give Loadscan LVS customers a visual interaction tool to achieve maximized payload efficiency utilizing the scan data generated in the LVS measurement process.

Standard Features

3D Payload Profiler Graphics

The LoadScan 3D Payload Profiler gives a graphical load representation for visual load shape and distribution feedback. Allows operators to detect off-centre or unsafe loading, load fragmentation and general load shape.

Manual Point-to-Point Measurement

Make manual measurements of load features or truck body dimensions with point-to-point measurements on longitudinal and transverse scan data cross-sections. Assists in manual estimates of tray capacity, load distribution, fragmentation, fill factor and so on.

Extended Features*

Load Distribution Analysis

How a load is distributed in the truck tray not only affects the efficiency of loading but also the wear on tires and machine as well as safety on the haul road. Avoid expensive tire blow-outs and protect your equipment by loading trucks correctly. Load distribution to the left, right, front or rear of tray can be determined from the centre-of-mass of the load, heap slope angles and other shape features*

Blast Fragmentation Monitoring

The distribution of rock fragment sizes (fragmentation) following blasting affects how easily the blasted rock is shoveled (digability) and the efficiency of truck loading with significant influence on productivity. The fragmentation within a truck load can be estimated from the 3D texture of the visible load surface and reported for every load for blast performance monitoring and optimization.*

Fill Factor Calculation

Loading trucks to capacity without over-loading is important for maximum productivity. Truck fill factor is a measure of how well a truck body is utilized. This can be computed from measured load volume, tray shape and size, load profile, fragmentation and optionally, externally supplied weight data.*

Rock-Fall Risk Identification

Visual highlighting of truck tray edge regions where the load is at risk of falling off the side, with configurable alarm thresholds allows operators to identify unsafe loads.*

Load Profiling gives you the tools to optimize truck loading practices for maximum haulage efficiency and increased productivity.